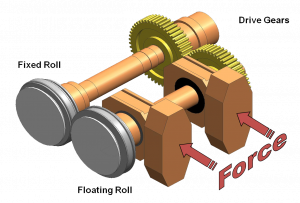

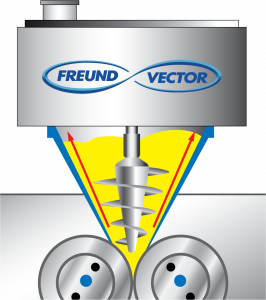

The TFC Roll Compactors are a continuous, directly compressible, dry granulation system to improve material flow characteristics and increase material density. A vertical product flow system uses a tapered feed screw to deliver the material to the fully contained compaction zone of the cantilevered rolls, increasing product yields and minimizing product fines.

The TFC roll compactor utilizes a unique roll system to compact powders into sheets or briquettes. The compacted sheets are milled to produce granules of a specific size. Particles that fall outside the desired size range can be recirculated back into the roll compaction system hopper, where the product can be reprocessed.